Sustainability

Pladur® is committed to sustainable buildings and protecting the environment. Most issues related to the environment, sustainability, life cycles, recycling and similar are handled in close collaboration with specialist organisations, with the aim or facilitating sustainable construction (environmental impacts, building adaptability and so on), and working for the comfort and safety of all (by reducing emissions and pollutions, among other measures).

The organisation’s main environmental goals are:

- Minimising atmospheric emissions.

- Reducing hazardous waste.

- Recovering non-hazardous waste.

- Optimising water consumption.

- Increasing energy efficiency

- Improving discharge prevention systems.

Indoor air quality

Pladur® classifies its products based on the emission of volatile organic compounds (compounds that are harmful to health), thereby obtaining the highest classification for most of its products

The Pladur® range also includes products such as Pladur® FON+ Air which absorbs up to 60% of formaldehydes and neutralises and transforms them into inert compounds, thus preventing their re-emission into the atmosphere and protecting people in the room.

Environmental product declaration

The Environmental Product Declaration (EPD) is drawn up in accordance with the requirements of current European standards. It is a standard document verified by third parties that provides information on the environmental impact of a product throughout its life cycle. Products with the EPD comply with International Standard EN ISO 14025.

Indoor air quality

Pladur® classifies its products based on the emission of volatile organic compounds (compounds that are harmful to health), thereby obtaining the highest classification for most of its products

The Pladur® range also includes products such as Pladur® FON+ Air which absorbs up to 60% of formaldehydes and neutralises and transforms them into inert compounds, thus preventing their re-emission into the atmosphere and protecting people in the room.

The organisation’s main environmental goals are:

- Minimising atmospheric emissions.

- Reducing hazardous waste.

- Recovering non-hazardous waste.

- Optimising water consumption.

- Increasing energy efficiency

- Improving discharge prevention systems.

Indoor air quality

Pladur® classifies its products based on the emission of volatile organic compounds (compounds that are harmful to health), thereby obtaining the highest classification for most of its products

The Pladur® range also includes products such as Pladur® FON+ Air which absorbs up to 60% of formaldehydes and neutralises and transforms them into inert compounds, thus preventing their re-emission into the atmosphere and protecting people in the room.

The organisation’s main environmental goals are:

- Minimising atmospheric emissions.

- Reducing hazardous waste.

- Recovering non-hazardous waste.

- Optimising water consumption.

- Increasing energy efficiency

- Improving discharge prevention systems.

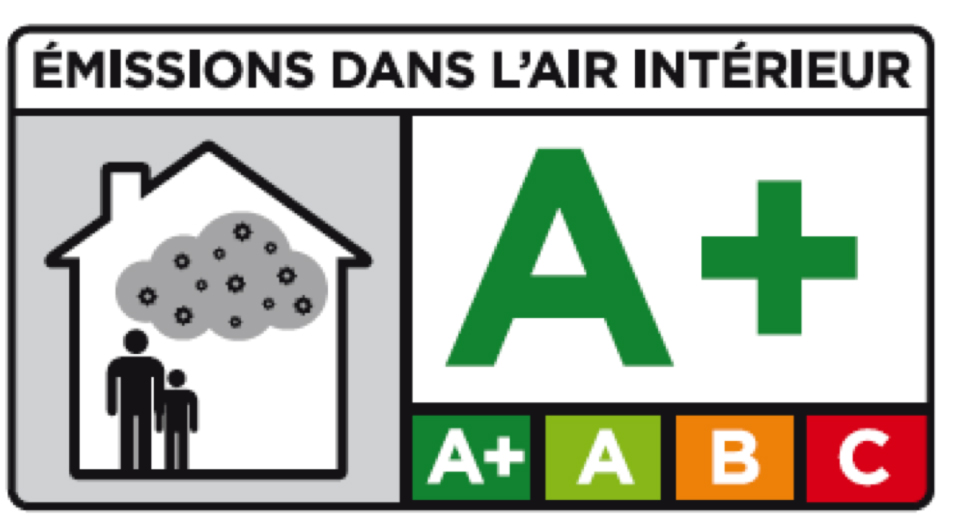

Product life cycle

The product life cycle flow diagram includes raw material extraction, manufacture, transport, installation, useful life on site, end of life and recycling.

LEED AND BREEAMR ®

Pladur® contributes to LEED, BREEAM® and VERDE® certification for buildings in which its solutions are used. In addition, Pladur® has agreements with institutions, associations and universities with the aim of developing and improving products as well as boosting innovation in the construction sector

Pladur® reaffirms its commitment to the environment, developing more sustainable products and systems and anticipating future European requirements, thus positioning itself as an innovative company and a sector leader.

IMPACT NOISE ACOUSTIC INSULATION

Insulation for impact noise is expressed using the value L’n T, w in dB. This value refers to the noise level in the receiving room, when a standardised impact machine is operating in the transmission room.

The lower the L’nT, w, the better the floor insulation.

LEED AND BREEAMR ®

Pladur® contributes to LEED, BREEAM® and VERDE® certification for buildings in which its solutions are used. In addition, Pladur® has agreements with institutions, associations and universities with the aim of developing and improving products as well as boosting innovation in the construction sector

Pladur® reaffirms its commitment to the environment, developing more sustainable products and systems and anticipating future European requirements, thus positioning itself as an innovative company and a sector leader.

IMPACT NOISE ACOUSTIC INSULATION

Insulation for impact noise is expressed using the value L’n T, w in dB. This value refers to the noise level in the receiving room, when a standardised impact machine is operating in the transmission room.

The lower the L’nT, w, the better the floor insulation.

LEED AND BREEAMR ®

Pladur® contributes to LEED, BREEAM® and VERDE® certification for buildings in which its solutions are used. In addition, Pladur® has agreements with institutions, associations and universities with the aim of developing and improving products as well as boosting innovation in the construction sector

Pladur® reaffirms its commitment to the environment, developing more sustainable products and systems and anticipating future European requirements, thus positioning itself as an innovative company and a sector leader.

IMPACT NOISE ACOUSTIC INSULATION

Insulation for impact noise is expressed using the value L’n T, w in dB. This value refers to the noise level in the receiving room, when a standardised impact machine is operating in the transmission room.

The lower the L’nT, w, the better the floor insulation.

Related Products

Ceiling FON+ C3-8

Pladur® FON+ improves acoustic comfort in all premises where it is installed.

Ceiling FON+ R8

For spaces requiring acoustic conditioning treatment or a distinctive decorative touch.

Pladur® Magna H1 25

Reinforced plasterboard that offers high resistance and on site efficiency, as well as maximum certified fire resistance.

Pladur® Ultra L-Tec

Laminated plasterboard for the configuration of continuous ceilings. Designed to facilitate installation and increase on site efficiency.